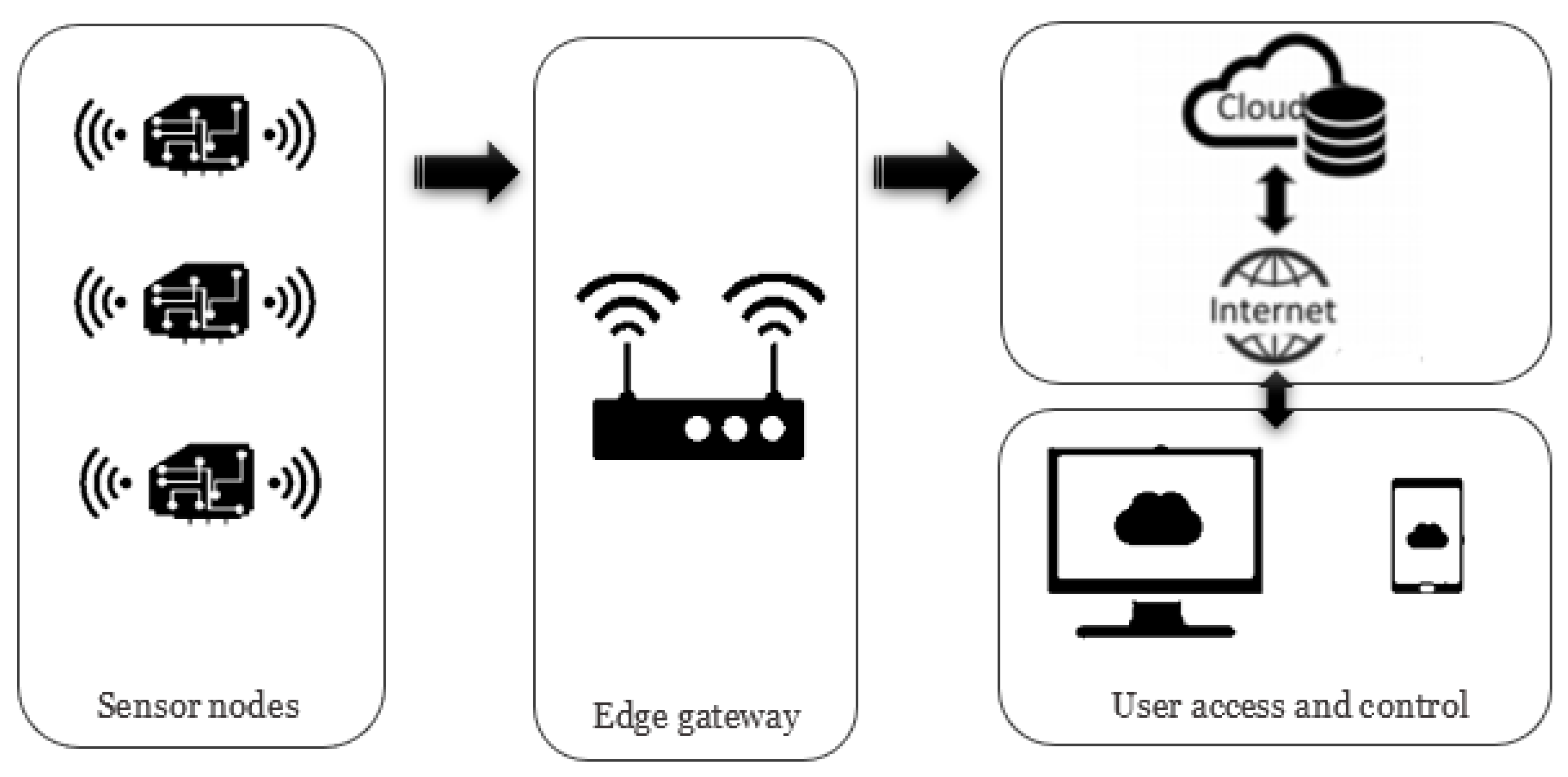

PDF Main Pipelines Corrosion Monitoring Device Circuit Diagram The Benefits of Implementing IoT for Corrosion Monitoring. As previously mentioned, IoT permits continuous, real-time, and accurate monitoring of oil and gas assets (pipelines, process vessels, tank farms, etc.) for corrosion-related defects. This allows faults to be detected in the early stages, thus minimizing repair work and associated downtime.

For instance, implementing real-time monitoring can reduce maintenance costs by up to 30% and prevent losses associated with pipeline failures, which can amount to millions of dollars per incident. The adoption of real-time corrosion monitoring solutions represents a significant advancement in maintaining pipeline integrity.

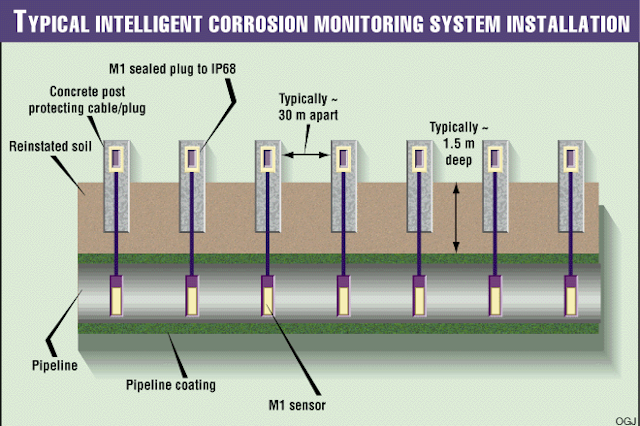

time corrosion monitoring Circuit Diagram

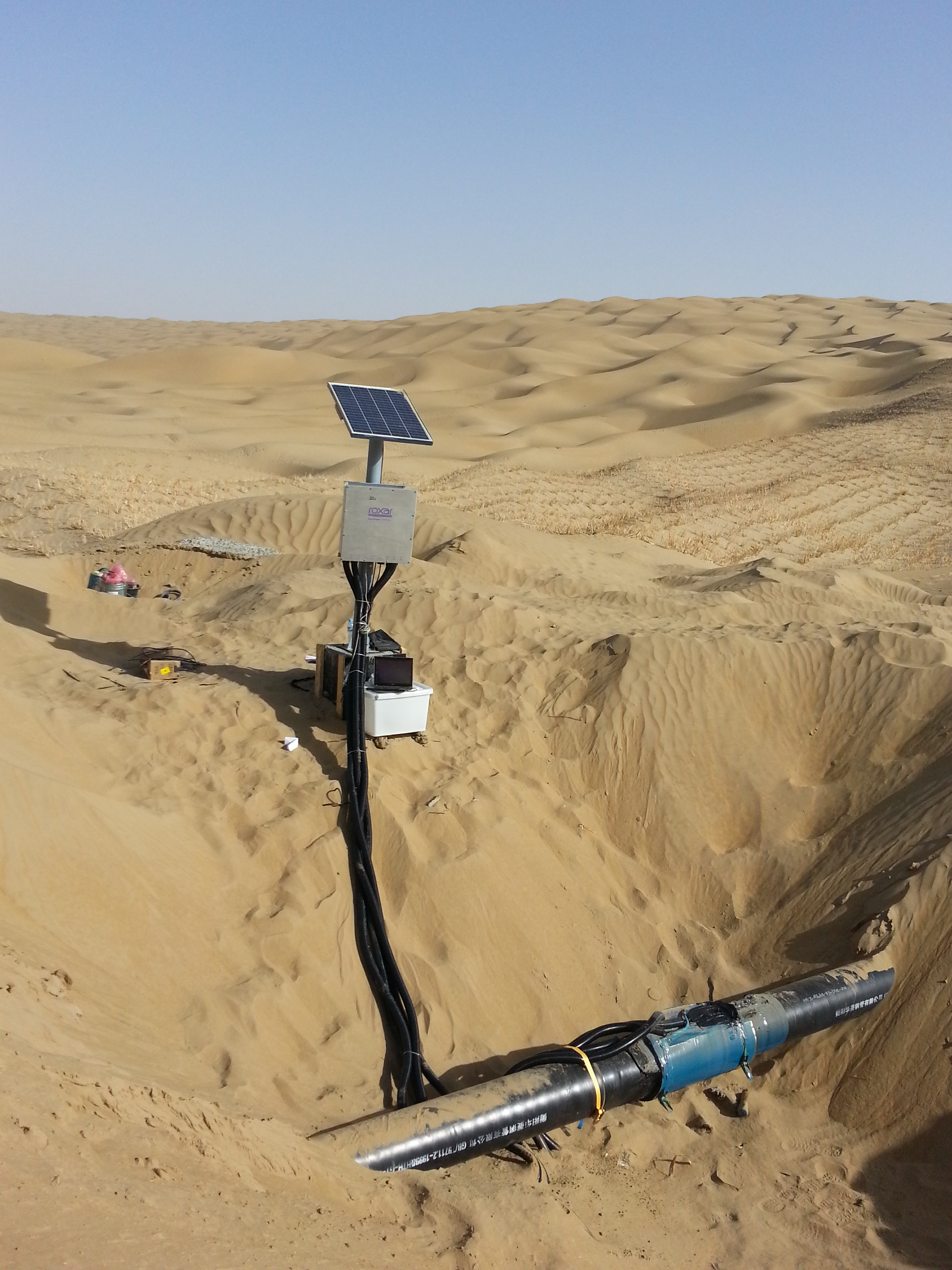

Case Study: Real-Time Pipeline Monitoring and Leak Detection with IoT Background XYZ Pipeline Company (Note: For the purpose of this report, we will refer to the company as XYZ Pipeline Company), a major player in the oil and gas sector, operates an extensive network of pipelines spanning thousands of kilometers across diverse terrains.

As you have learned in this post, you can build an IoT-based automated pipeline inspection system to store your data in a data lake. The data coming from various ultrasonic sensors is then stored in S3 where you can perform analytics on the data using Athena. Visual dashboards are generated using QuickSight.

Implementing IoT Solutions for Pipeline Monitoring Circuit Diagram

of an ultrasonic monitoring device for pipeline corrosion in a specific oil and gasfield has been investigated in this paper. Researching the gathered real time data and mining the data gives more insights into tackling the corrosion monitoring. There is also scope for analyzing and understanding why and how corrosion happens, how the environment